International leader in nuclear energy

Framatome breaks ground on $50 million expansion in Lynchburg, Va.

Find out more

Framatome’s teams design, build and service the nuclear steam supply system (NSSS). For more than 60 years, the company has been present at every stage of the process on all types of reactor technologies.

We are recruiting

Like you, we want a brighter future.

Together we will enable clean, safe and economical low-carbon energy to meet the global ambition for a better tomorrow.

Together we will enable clean, safe and economical low-carbon energy to meet the global ambition for a better tomorrow.

Discover Framatome

Framatome is a NSSS designer and manufacturer, supplier of equipment, services and fuel for high levels of safety and performance

€4 billion

in revenue in 2023

18,000

employees of all nationalities

64

sites worldwide

Featured solution

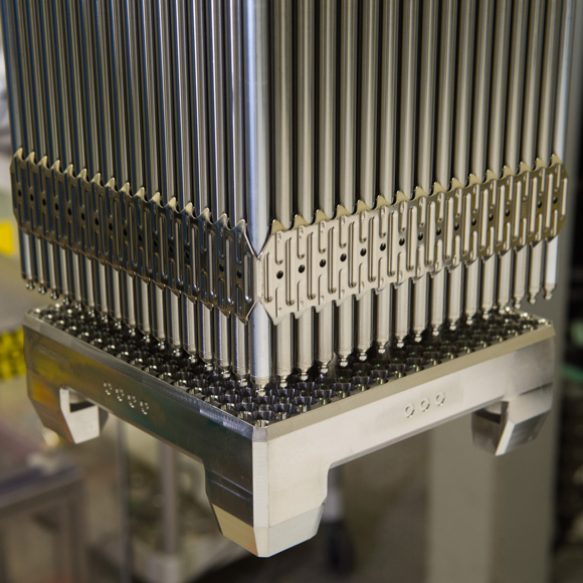

PROtect program: Enhanced Accident Tolerant Fuel assemblies (E-ATF)

PROtect provides improved fuel reliability due to increasing wear resistance, very low oxidation kinetics under high-temperature steam and increased fission gas retention

PROtect provides improved fuel reliability due to increasing wear resistance, very low oxidation kinetics under high-temperature steam and increased fission gas retention