September 19, 2022 – Framatome has completed installation of the first 3D-printed, stainless steel fuel component at the Forsmark Nuclear Power Plant, operated by Vattenfall in Sweden. In collaboration with KSB SE & Co. KgaA, the ATRIUM 11 upper tie plate grids were designed, manufactured, and installed in Forsmark Unit 3 for a multi-year irradiation program.

“Advancements in the integrity of components manufactured using 3D-printing are revolutionary in the generation of safe, reliable low-carbon energy for long term operations,” said Lionel Gaiffe, senior executive vice president of the Fuel Business Unit at Framatome. “We appreciate Vattenfall for opening its doors and providing a steppingstone for future innovations and developments that will replace conventional manufacturing.”

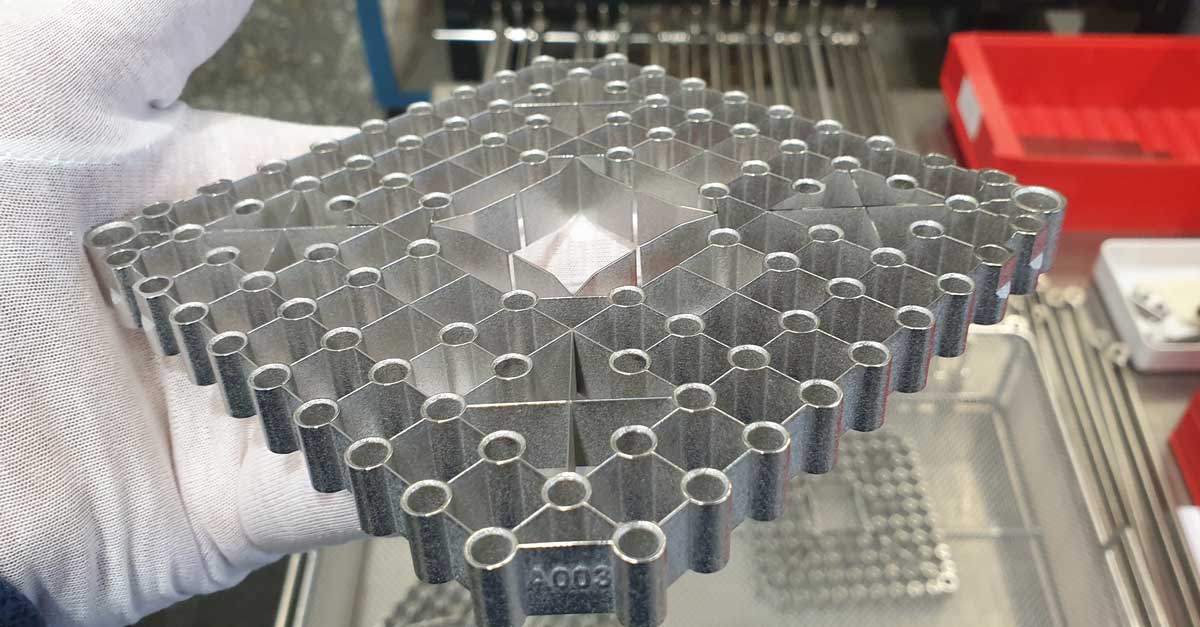

Located at the top of the ATRIUM 11 fuel assembly, the upper tie plate grid is a non-structural weight-bearing component that secures fuel rods and retains larger debris from entering the fuel assembly from the top. Upper tie plate grids are easily inspected, and samples are accessible for qualifying this new manufacturing process for in-reactor use as needed.

“The safe operation of fuel assemblies is key to Vattenfall,” said Ella Ekeroth at Vattenfall Nuclear Fuel AB. “Along with this basic principle, our contributions to the development of efficient and reliable manufacturing processes are in the best interest of the entire nuclear industry. The overall goal of these activities is to maintain and further enhance safety and enable economically viable long term operations.”

During the conventional manufacturing process, upper tie plate grids are laser welded, using stamped comb-like sheets that require additional manufacturing steps and operator oversight. Additive manufacturing streamlines the manufacturing process and increases design options for enhanced functionality and improved performance.

Framatome’s initiative to introduce additive manufacturing to nuclear fuel began in 2015 and is focused on stainless steel and nickel-based alloy fuel assembly components. In 2021, a 3D-printed stainless steel fuel assembly channel fastener created by Framatome in collaboration with Oak Ridge National Laboratory (ORNL) was loaded in a U.S. commercial BWR nuclear power plant. Framatome fuel experts in France, Germany and the U.S. developed this technology in close collaboration with customers worldwide.

Framatome’s 3D-printed ATRIUM 11 upper tie plate grid