In a context of growth and for the first time in 7 years, on May 18, 2019, the Jarrie site (Fuel BU, Auvergne-Rhône-Alpes region) organized a family day.

A great time was had by all:

"This open day gave me the opportunity to visit Framatome's Jarrie site. I found the visit very interesting and instructive, with a very warm welcome from the guides. Thanks for letting us find out more about what you do and your know-how – and for giving us such a warm welcome!" said Margaux, one guest invited by an employee.

"We believe it was important to create this moment to share what we do with our families to show them that there is a positive dynamic at Jarrie. I would like to thank all those who took part for their involvement and energy which made this day such a success" underlines Silvino Caetano, Site Director.

Find out more about the Jarrie site, the Fuel BU and current recruitment needs:

The Framatome Jarrie site is located in a geographical area characterized by significant industrial activity based on chlorine chemistry with the Arkema site and the Pont de Claix platform near Grenoble. The products manufactured on the Jarrie site are zirconium, hafnium and oxides and salts. The site operates at the front end of the zirconium transformation cycle and is focused around two main sectors, chemistry and metal.

To underpin its development, the Jarrie site recruits on a regular basis for all of the jobs at the site, including chemistry operators, maintenance technicians and for other posts. Consult the available offers in the Join Us section of the Framatome website or contact Vincent Rousson, Human Resources Manager for the Jarrie site:

vincent.rousson@framatome.com

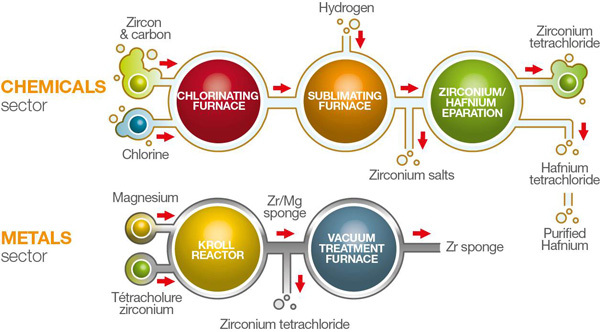

Main stages of the fabrication process at Jarrie:

Two main operating units, chemicals and metals.

The Chemicals Operating Unit converts the feed material, fused zirconia, into zirconium tetrachloride through a series of processes conducted in this unit's three facilities.

- The carbochlorination facility: fused zirconia and carbon black are mixed together and made to react with chlorine in high-temperature furnaces, producing raw hafnium-containing zirconium tetrachloride.

- The sublimation facility uses furnaces to produce purified hafnium-containing zirconium tetrachloride.

- The zirconium-hafnium separation facility uses distillation to separate nuclear grade zirconium tetrachloride from hafnium tetrachloride. This operation is carried out using a 40-meter-high extraction column.

The Metals Operating Unit converts the zirconium tetrachloride produced in the previous step into zirconium "sponge".

- In the Metals facility, the zirconium tetrachloride is placed in reaction furnaces containing solid magnesium. A pseudo-alloy of zirconium and magnesium is obtained at the end of the hot conversion process. It is then refined by distillation to remove the magnesium and obtain the zirconium sponge.

- In the milling workshop, the sponge is crushed and flaked in an inert gas atmosphere. The pieces of sponge are sorted visually and packaged in 200 kg drums.

Products manufactured at the Jarrie plant:

- Zirconium: a metal with a density of 6.5 that is produced in the form of a sponge from raw mineral and intended for subsequent conversion into zirconium alloy components for the nuclear industry.

- Hafnium: hafnium tetrachloride, a byproduct of nuclear grade zirconium production, is used to form electrolytic hafnium crystals that are refined to produce ultra-pure hafnium, primarily for aeronautic applications.

- Salts and oxides: zirconium tetrachloride and hafnium tetrachloride are sold as chemical reagents. They are also used as a raw material for pharmaceutical and electronics applications, among others. Hafnium oxides are used for applications in industrial ceramics, optics and the automotive sector.