Swiss operator has been relying on Framatome solution expertise for decades

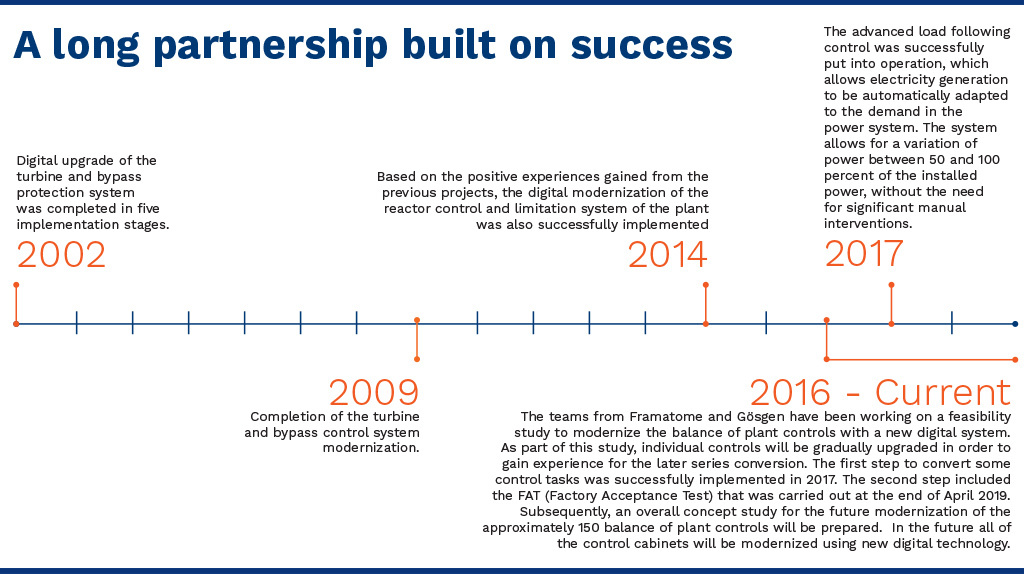

The Gösgen* (KKG) nuclear power plant, operated by Kernkraftwerk Gösgen-Däniken AG, sets the example for a successful transition from analog to digital control technologies and the advantages it offers. For decades, the operator, in cooperation with Framatome, gradually increased the performance and safety of its plant through various technical optimizations, leading with its digital instrumentation and control (I&C) system. The positive experience gained from both the Gösgen and Framatome teams gives customers confidence that Framatome has the expertise to successfully master their transitions from analog to digital I&C technologies.Framatome supports Gösgen projects of all sizes – from extensive modernizations to smaller subprojects, and this success story continues. Framatome, together with Gösgen, successfully completed the electrical systems and I&C replacement on four emergency diesel generators, and is currently working on a project to replace its reactor protection system.

New digital I&C for emergency diesel generators

One of the most important safety functions in a nuclear power plant is the emergency power supply of the safety system. In the event of an external power supply failure, the continued safe operation of the plant must be ensured. In Gösgen, Framatome replaced the electrical systems and I&C on four emergency diesel generators.“The joint team effort and the close cooperation between Framatome and Gösgen in all phases of the project were crucial to ensure the successful and early completion of the upgrade”, said Karsten Dressbach, Vice President of the Business Line Products & Projects at Framatome.

On 15 February 2019, the last of the four permanently installed emergency diesel generators was successfully converted to Framatome’s digital safety I&C platform, TELEPERM XS. As with the first three conversions, this installation demonstrates Framatome’s commitment to performance in delivering on time.

Signed contract regarding the replacement of the reactor protection systems

Another important milestone in the long standing cooperation between Framatome and Gösgen, is the contract award for the replacement of the reactor protection system signed on 4 March 2019.To further increase the plant safety and the planned long-term operation of the KKG, the entire reactor protection system in the switchgear building will be modernized. Once again Framatome‘s proven instrumentation and control (I&C) platform, TELEPERM XS, will be used. The installation and commissioning of the new reactor protection system are scheduled for the plant’s 2022 outage.

“This contract marks another important milestone in the long-lasting cooperation between Gösgen NPP and Framatome,” said Frédéric Lelièvre, Framatome’s senior executive vice president in charge of Sales, Regional Platforms and the Instrumentation and Control Business Unit. “It is yet another example showing how, over the years, we have managed the transformation from analog to digital technology successfully together.”

Solution expertise from Framatome – the advantages of digital I&C

The advantages of digital I&C are that it offers significantly more functionality than analog systems, and it allows for more efficient data processing and storage.Moreover, digital I&C benefits from the efficiency of software-based tools in order to make it easier to modify, test and simulate implemented functions, as well as to detect and replace failed components. In addition, there is the better availability of spare parts, which prevents potential plant operating downtimes due to components that are no longer available.

Digital systems have improved capabilities (e.g. fault tolerance, self-testing, signal validation, process system diagnostics) that provide the basis for achieving the required reliability and safety. Such functions minimize maintenance intervention and significantly reduce human error. The new technology also requires fewer service personnel.

Last but not least, digital systems have a higher level of acceptance among the new generation of plant operators, as they are already familiar with computer-aided applications.

Framatome modernizes I&C systems according to specific customer requirements. These solutions integrate seamlessly into existing systems and are applicable to all reactor designs (PWR, BWR, VVER, CANDU and more). Framatome also performs safety analysis and qualification, supports licensing and interaction with regulatory authorities, provides operator training and updates documentation.