Design and Engineering

Engineering confidence through testing, simulation, and expertise.

Framatome’s Technical Centers offer a comprehensive suite of laboratory, testing, simulation, and analytical services to support innovation, qualification, and operational excellence in the nuclear and high-stakes industrial sectors. Backed by decades of experience, specialized facilities, and in-house engineering expertise, we help customers solve complex technical challenges while ensuring safety, performance, and compliance.

Technical Expertise and Simulation Resources

Nuclear Power Plant equipment operates under challenging environmental conditions. The Technical Center contributes to their safe operation by actual testing, analyses and qualification engineering.

With expertise and unique laboratories, we support new reactor developments, equipment suppliers, manufacturing and plant maintenance. We develop and commercialize a Finite Element Analysis (FEA) software (SYSTUS) and perform structural and computational fluid dynamics (CFD) studies. Our technial centers serve nuclear markets and beyond.

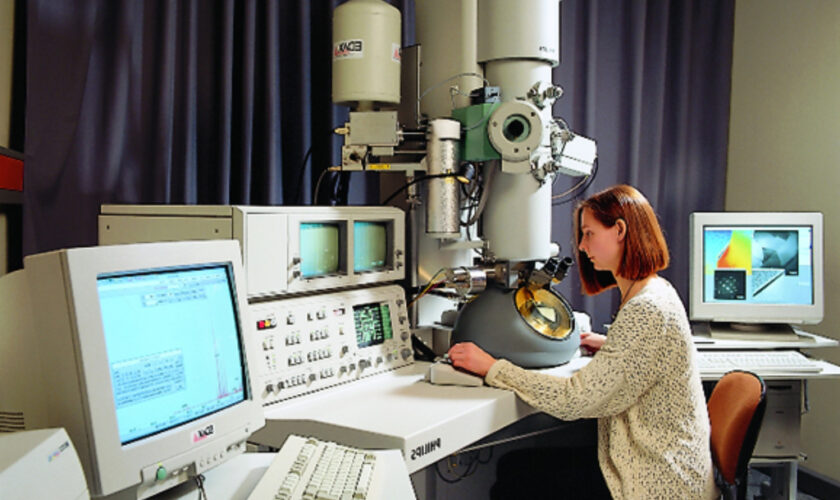

Framatome offers comprehensive material support from testing to lifecycle evaluation. Services include root cause analysis, fitness-for-service (FFS), corrosion testing, welding development, additive manufacturing, and hot cell evaluations. Mechanical testing (tensile, toughness, fatigue) and numerical fracture mechanics support qualification, repair, and long-term operation of critical nuclear components.

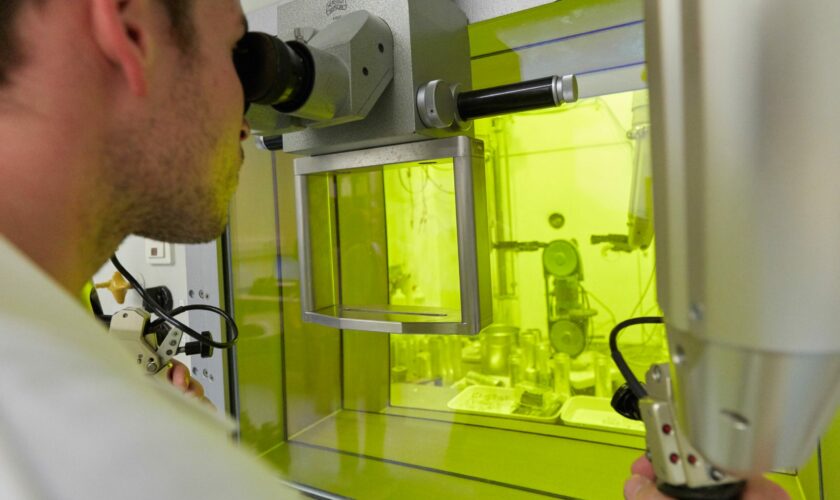

Framatome’s Technical Centers offer chemical and radiochemical analysis for nuclear materials, effluents, waste, and environmental monitoring. We provide radioprotection services and hot cell testing for highly irradiated and activated materials. Our laboratories support root cause investigations, material characterization, and post-irradiation examination to ensure plant safety and regulatory compliance.

We support successful nuclear equipment qualification through engineering strategy, regulatory compliance, and physical testing. Our experts manage qualification programs using in-house and external test facilities. Services include qualification planning, environmental and mechanical testing, preservation, and commercial grade dedication, aligned with ASME, RCC-E, IEEE, and other international standards.

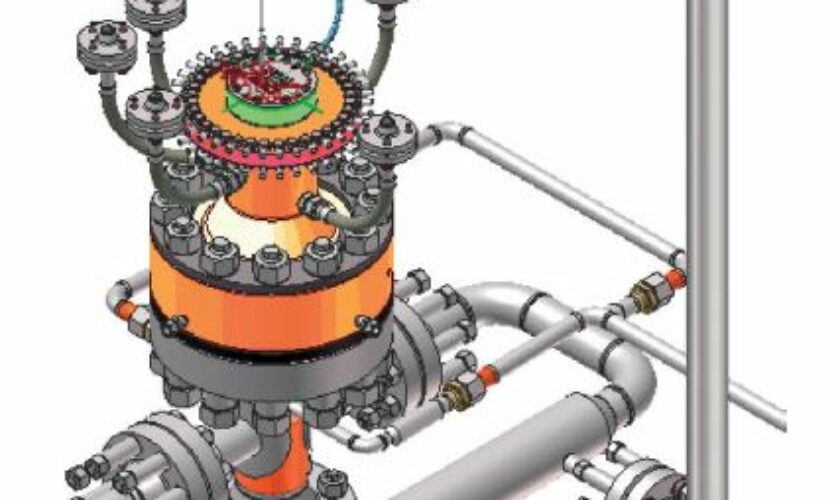

Framatome operates world-class thermal-hydraulic test loops and mechanical test benches for valves, pumps, RPV internals, and passive cooling systems. Our facilities support LOCA simulations, vibration, shock, and full-scale system testing. We provide component qualification, code validation, data generation, on-site support, and training, with over 40 years of testing expertise.

Framatome offers structural simulation services using SYSTUS, Code_ASTER, and ANSYS, with full support for ASME, RCC-M, and ESPN codes. Expertise includes fatigue and fracture mechanics, welding simulation, and thermo-mechanical coupling. Our Calculation Training Center in Burgundy provides hands-on education in nuclear simulation software, regulation, and mechanical theory.

We deliver advanced CFD simulations using ANSYS Fluent, STAR-CCM+, and OpenFOAM to support nuclear design, fuel performance, and process optimization. Services include multiphysics coupling, high-fidelity flow modeling, energy efficiency analysis, and predictive metamodeling. Supported by HPC (CPU/GPU) computing, our simulations reduce cost, improve accuracy, and extend equipment life.

Our laboratories in Le Creusot and St-Marcel (France), and Erlangen and Karlstein (Germany), offer robust infrastructure backed by experienced staff. All services are performed under ISO 9001 quality assurance and ISO 17025-accredited procedures.

Find out more by consulting the respective baskets below.