Rod control cluster assembly lifetime management

A3280

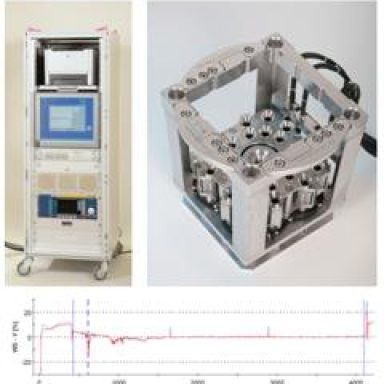

The availability and planning of functional Rod Control Cluster Assemblies (RCCAs) are essential for the safe operation of PWRs. In addition to safety, operators must also prioritize cost-effectiveness and waste management.

The main factors that limit the lifetime of RCCAs can be categorized based on their predictability: Mechanical damage, Fluence restrictions, Cracks in the cladding, Wear of guide cards.

In response to these constraints, our solution aims to optimize the number of RCCAs required throughout the plant’s lifetime, ensure the optimal use of functional RCCAs to reduce nuclear waste, and mitigate the risk of RCCA shortages toward the end of the plant’s operational life.

Related solutions

Fuel design & procurement

You need to achieve safe and efficient operation of your plant; Fuel design and assemblies are a key lever to reach this goal. Framatome uses advanced codes and methods for the design and analysis of our fuel assemblies. We design, manufacture and deliver all fuel-related components and all types of BWR and PWR fuel assembly designs. We can perform all relevant calculations from general fuel management up to dedicated licensing for the highest performance and safety.

Fuel services & solutions

Plant operators need fuel after-sales services to achieve the greatest value from the core. Framatome’s service engineers support you when taking delivery of fuels and during reloading activities, after stringent quality inspections. We also offer consultation and support for flexible fuel cycle solutions, customer training and the development of special tools for fuel inspection and repair, such as mast-sipping.

Long-term operations

In order to optimize your asset, you can decide to run your plant beyond its designated lifetime. Safety being a priority this decision is driven by the need for low carbon and competitive energy. Framatome works closely with you on your plant’s long-term operations strategy, covering license renewal, aging and asset management, modernization and upgrades, and other long-term challenges.

Outage services

You can prevent risk of technical issues causing delays and drift of outage costs by relying on experienced teams with a wealth of expertise. Framatome’s highly-skilled teams deploy proven, innovative technologies and solutions backed by service-proven knowledge of utilities’ objectives for reactor maintenance, inspections, fuel reloading operations, and outage management optimization. Our solutions ensure our customers avoid costly outages and outage extensions.

Safety in operation

You have to demonstrate that your plant’s systems and functions are fulfilling the requirements of safety authorities. Framatome provides safety analysis solutions to support you when reviewing your design requirements, including customer training. We also provide emergency preparedness, including emergency power supply, radioprotection, and fire protection solutions and expertise. In addition, we either propose safety system upgrades or demonstrate that the current design meets all new requirements.