Framatome refocuses its activity on its core business: being an “NSSS designer and manufacturer”

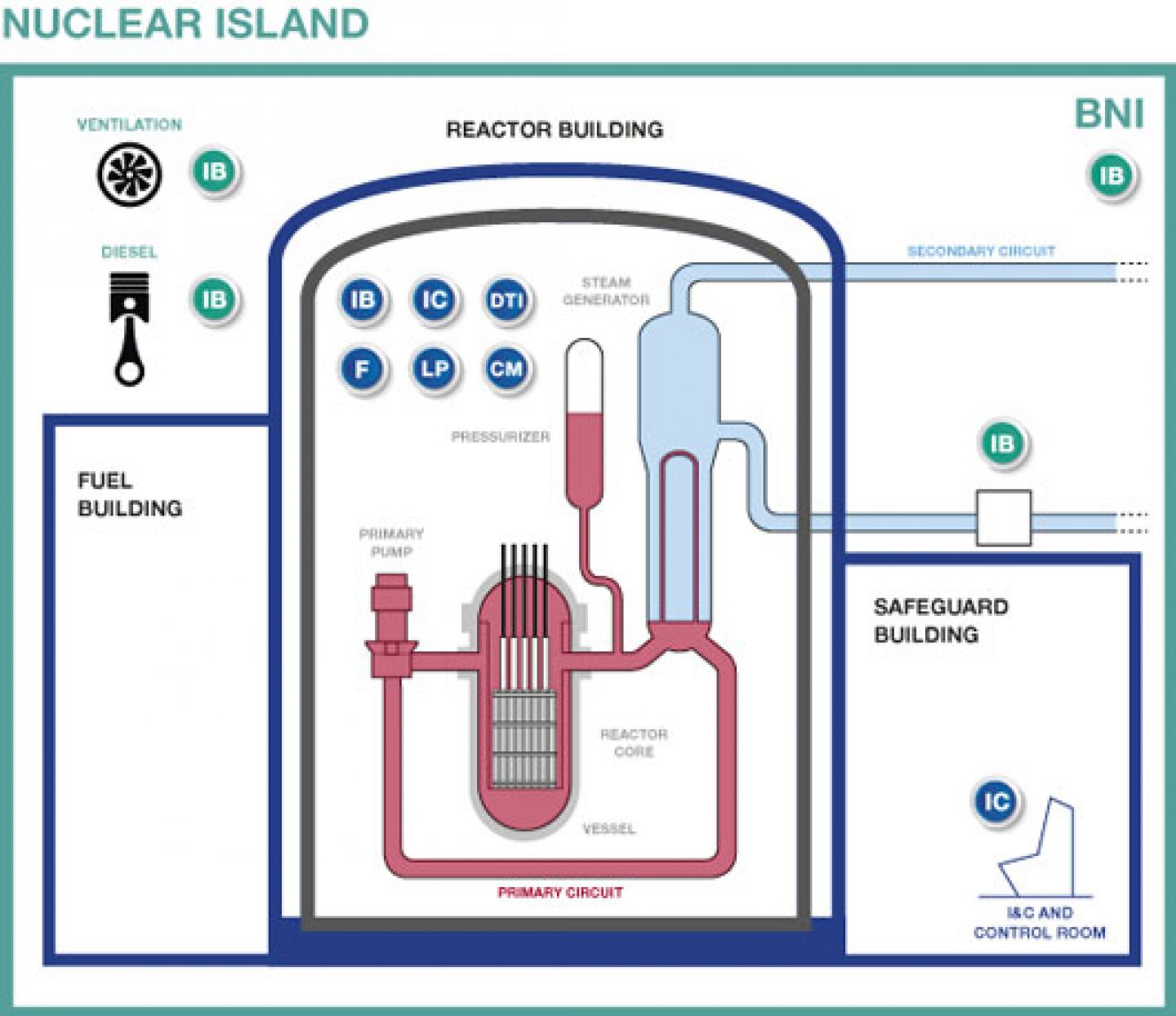

General view of the Nuclear ISland of Hinkley Point C - (c) EDF Energy

General view of the Nuclear ISland of Hinkley Point C - (c) EDF Energy

As part of the reorganization of the French nuclear sector, Framatome is refocusing its activity on its historical core business: the design, manufacturing and sales of nuclear steam supply systems (NSSSs), of components including safety instrumentation & control (I&C), as well as fuel and associated services.

Nuclear power plant user’s guide

The nuclear steam supply system (NSSS) is the part of the nuclear power plant which is used to produce steam to supply the turbine generator units which in turn generate electricity.

This “NSSS” contains the nuclear reactor itself, where the fuel undergoes a fission reaction which releases a large amount of energy. Acting like a transmission belt, the reactor coolant system (or primary circuit), which uses pressurized hot water for “PWR”-type reactors, transfers this heat to the steam generator which in turn supplies the secondary circuit with steam to drive the turbines that generate the electricity.

We explain how the process works in more detail below.

Nuclear power plants are invariably made up of two parts:

- a nuclear island which houses the NSSS and whose main unction is to supply steam,

- and a conventional, non-nuclear island, devoted to the generation of electricity, the turbines of which are driven by the steam.

They also incorporate:

- equipment for the monitoring and control of installations,

- as well as connected equipment.

The nuclear island

The nuclear island (NI) is the nuclear zone in the strict sense.

It is made of:

- a nuclear steam supply system (NSSS) which contains the fuel,

- as well as the various equipment necessary for the operation (auxiliary systems, facilities for the receipt and interim storage of fuel) and safety (safeguard systems) of the system as a whole.

1 – The nuclear steam supply system (NSSS)

The nuclear steam supply system (NSSS) uses the heat released by the nuclear reaction to heat up the reactor coolant (or heat transfer) fluid. For Pressurized Water Reactors (PWRs), this is hot water under pressure.

This coolant water is in turn used to heat the water in the secondary circuit and transform it into steam.

It is comprised of:

- a reactor vessel made of steel which contains the fuel assemblies that constitute the reactor core. This generates a nuclear fission reaction, which is controlled by means of neutron-absorbing rods and releases an intense heat in the reactor

- a primary circuit which extracts the heat generated in the core of the reactor. In practice, electrically-powered pumps circulate the coolant within a closed system of pipes, which works in a loop. In this way, the hot water is delivered to 3 or 4 steam generators (the number of generators depends on the power of the reactor) which act as a transmission belt to transfer the heat to the secondary circuit.

- a pressurizer which keeps the water in the primary cooling system, heated to a temperature of over 300 °C, under pressure to prevent it from boiling.

Diagram of the nuclear island. The DTI (Engineering and Engineering Department), CM (Components), LP (Projects), IC (Instrumentation and Control), F (Fuel) or IB (Installed Base) dots correspond to the names of the entities involved in the construction of the nuclear island.

2 – The safeguard systems

In the event of a failure or accident (safeguard systems), these systems ensure that the essential safety functions of the nuclear island, in particular the cooling of the core, the evacuation of heat and the containment of radioactive materials, are maintained.

3 – The auxiliary systems and facilities for the management of fuel and the treatment of waste.

The auxiliary systems perform all the operations that are necessary for the NSSS to run. These for example include the system which takes over from the steam generators to evacuate the residual power when the reactor is shut down.

The fuel management facilities essentially consist of the pool for the interim storage of used fuel, as well as systems for the loading and unloading of new and used fuel.

The facilities for the treatment of effluent and waste allow the liquid and solid effluent generated by the operation of the plant to be purified and/or conditioned, in accordance with environmental criteria or the specifications of interim storage/disposal sites.

The conventional island

The conventional island designates all Electricity Generation Installations (EGIs). This non-nuclear part of the plant does not differ in any way from a conventional thermal power plant (a coal, fuel or gas-fired plant for example).

A conventional island in particular includes a steam turbine with a condenser (to condense the steam into water, then recycle it back to the steam generators), an alternator and a transformer.

1 – The secondary circuit, steam generator and alternator

The cold water from the secondary circuit enters the steam generator, reaches boiling point and exits in the form of steam. A system of baffles and filters separates off the droplets in suspension to obtain a dry steam which is used to turn the turbines at a speed of 1,500 revolutions per minute and drive an alternator generating an alternating electric current at 50 Hz.

2 – The transformer

The current generated by the alternator is then sent to a transformer which raises its electrical voltage, allowing it to be transported over the grid by very high voltage electric power lines.

The instrumentation and Command (I&C)

The instrumentation covers all the tools for measurement, surveillance, process control and supervision, and related equipment.

The I&C system of the plant itself meets the specifications imposed by the process, nuclear safety and operating conditions.

- The tools used include:

- sensors to perform measurements,

- programmable logic controllers,

- as well as other centralized means of control and supervision available to operators (control desks, alarms, etc.).

It is made up of:

- the safety I&C, the purpose of which is to activate and maintain the functions which are important for the safety of the plant: halting of the neutron reaction, cooling of the core, containment, etc. This I&C in particular includes the core surveillance instrumentation.

- the operational I&C, which performs the other functions (power regulation, operation of auxiliaries, etc.)

Balance of Plant

In addition, the connected equipment – better known as Balance of Plant (BOP) equipment – covers all items of mechanical and electrical equipment not related to the operation of the nuclear island and the turbine:

- the feedwater intake station and cooling towers of the condenser,

- administrative buildings,

- station for the evacuation of generated power, etc.