Services and maintenance: ensure the sustainable operation of facilities

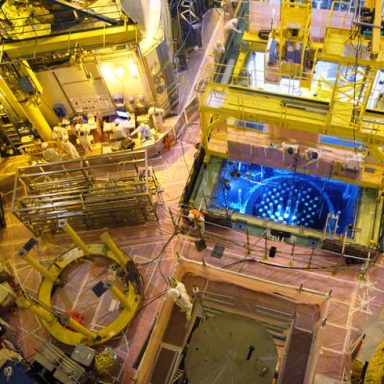

Outage at Golfech power station (France) © EDF

Outage at Golfech power station (France) © EDF

Innovative solutions to improve the competitiveness and availability of nuclear facilities while ensuring safe operations

Framatome has over six decades of experience acquired on more than 380 reactors. We work on sites worldwide to carry out maintenance operations on components of the primary loop and for the modernization of auxiliary systems.

With our comprehensive portfolio of innovative solutions and technologies, we enable our customers to:

- Control their costs while maintaining unit outage schedules

- Safely and efficiently modernize or install new equipment

- Rely on our engineering expertise and capacity

Maintain reactors in operation

Our highly-skilled teams provide their know-how and knowledge of nuclear facilities. They supply innovative products and services to our customers for the sustainable generation of safe and competitive, low carbon energy. They work on all types of reactors worldwide.

Leveraging our expertise and experience in nuclear safety, Framatome develops solutions for all critical industries to make them more robust and resilient in the area of cybersecurity.

Main areas of activity:

- Specialized, preventive and corrective maintenance of nuclear facilities

- Optimization of outage cost and duration

- Development of specialized equipment and non-destructive examination

- Safety and design studies

- Chemistry products and services to improve the performance of the primary and secondary coolant systems

- Cybersecurity solutions for the management of critical assets

- Engineering for facilities in operation and undergoing dismantling

Worker inspecting welds on pressure-retaining parts housing the control-rod drive mechanisms © EDF, Alexis Morin

Modernize and extend the service life of facilities

To bring about lasting improvement in the operation of its customers’ industrial assets over the long term, Framatome proposes solutions for the modernization of facilities and the optimization of their service life.

Thanks to proven international expertise in engineering, maintenance and design on all types of reactors, Framatome’s solutions provide operators with the guarantee of safety and competitiveness needed for the long-term operation of their facilities.

Main areas of activity:

- Replacement of heavy and mobile components of primary and secondary loops

- Replacement of auxiliary systems

- Studies on extension of service life

- Solutions to improve the nuclear safety of facilities

- Solutions to uprate the power of reactors

- Modernization of electrical systems

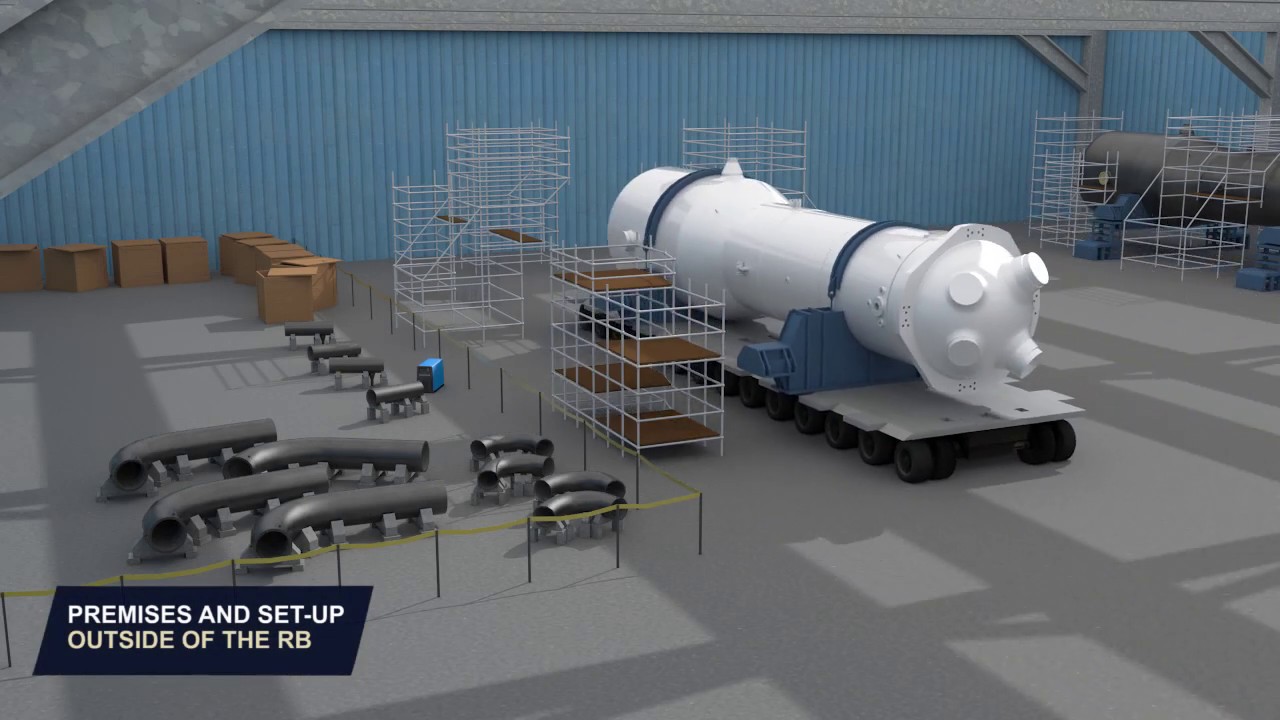

Video: Steam generator replacement

The video above is a 3D animation of a steam generator replacement operation, carried out with our customer, EDF.

[Narrator speaks]

In order to extend the life of its nuclear power plants and bring their level of performance back to the initial level, EDF has programmed several major maintenance operations on these 1300 Megawatt units, in particular the replacement of the Steam Generators, known as SGR operations. This highly specialized technical project is being carried out for EDF by Framatome as prime contractor.

The completion of the project to replace the four steam generators is the result of four years of design studies, surveys and certification work to qualify the maintenance operation.

Once the control rods have been lowered and the building’s guard rail has been decompressed the steam generator replacement operations begin. A specific organization is put in place by Framatome to limit the impact of the duration of the shutdown as much as possible.

A 1300 MWe unit is made up of a reactor pressure vessel, a pressurizer, four pumps and four steam generators which form the primary circuit.

A compound and specific premises have been set up outside the reactor building for Steam Generator Replacement (SGR).

Offices close to the reactor building are installed at the foot of the equipment access airlock.

An external gantry is mounted for handling of the steam generators (SG).

[The narrator stops here and animations of operations outside and inside the reactors scroll by, followed by annotations specifying what is being done.]

The machining and welding of the new secondary sections begins. This work is carried out outside the reactor building.

Protective tarpaulins for the bunkers are installed around the generators inside the reactor building. The insulation is then removed from the primary and secondary parts of the four steam generators. This operation is followed by the installation of biological protection.

Dimensional checks of the primary pipework are carried out. Next, the Main Steam System (Circuit de vapeur principal (VVP)) and Normal Steam Generator Water Supply System (Système d’alimentation normale en eau des générateurs de vapeur (ARE))pipes are cut and evacuated. Again, dimensional checks are made on the primary pipework.

Handling systems are installed and set up to facilitate the evacuation of the steam generators to be replaced. Once the generators have been removed from the reactor enclosure, the primary pipework decontamination operations are carried out.

With the old steam generators removed, the new steam generators are transported to be installed in the reactor. New ARE and VVP sections are installed and connected to the new SGs. Dimensional checks of the pipework are carried out one last time. Automatic pipe welding, non-destructive testing and ultrasonic testing are then carried out.

Finally, the protective equipment is removed and the insulation is refitted around the steam generators.

[The narrator continues]

The steam generator replacement operation is complete. Recertifica1tion tests are carried out in order to enable the unit to be restarted.

The unit fitted with these new steam generators has now been restored to its initial performance level.

Commissioning of new facilities

Framatome assists operators with the assembly and commissioning of their new facilities, ensuring these operations are carried out safely . Our teams are present at their side right from the engineering and design phases. They can then provide project management and technical assistance to project management on complex projects.

Framatome also designs and supplies the technological building blocks on new build projects for power reactors, including for non-Framatome reactor designs, such as VVER or CANDU reactors, for civil research reactors like the ITER nuclear fusion tokamak or specialized equipment for the production of medical isotopes.

Main areas of activity:

- Assembly of primary and secondary loops

- Design and installation of electrical systems and emergency diesel generators

- Containment and ventilation solutions

- Design and installation of systems for the production of medical isotopes

- Systems and products for equipment diagnostics and monitoring

- Assistance with obtaining certifications and qualifications

- Specialized and multidisciplinary engineering (design, calculations, mechanical engineering, civil engineering, etc.)

Key figure

380+

reactors serviced worldwide

News

Solutions portfolio