Valserve

90 Rue Challemel Lacour

69007 Lyon

France

Tél : +33 4 78 61 67 00

contact@valserve.com

Aerial view of the Valserve location in Lyon, France © Valserve

High Performance Valves for Strategic Sectors

Based in Lyon, France, Valserve (formerly Velan SAS) is one of the world’s leading companies in the design and manufacturing of safety related valves for Nuclear Power, Cryogenics, Defense, Space, and Big Science sectors.

Since 2025, Valserve is a 100% subsidiary of the Framatome Group, further strengthening its international position and strategic role with its customers.

Recognized Industrial Expertise

Thanks to our fully integrated manufacturing facility, we manage the entire production chain from design to manufacturing and on-site maintenance. Our products comply with the most demanding international design codes and regulations. Our commitment is built on four pillars: safety, quality, performance, and reliability, backed by over 50 years of proven operational experience and more than 250 product qualification reports.

Global Presence

Valserve safety related valves are operating in over 180 nuclear power and military reactors worldwide, as well as in numerous cryogenic facilities handling liquefied natural gas (LNG), hydrogen, oxygen, or liquid helium at temperatures down to absolute zero.

350

employees

20.000 m²

manufacturing site

180.000

nuclear and cryogenic valves delivered over more than 50 years

Valserve activities

Nuclear Power New Build

Design and manufacturing of Safety Related Valves for new nuclear power reactor projects including:

- European pressurized reactor (EPR)

- Water-Water Power Reactor (VVER)

- AP1000

- Hualong Pressurized Water Reactor (HPR)

- Fast Breeder Reactor (FBR)

- High-Temperature Reactor (HTR)

- Small Modular Reactor (SMR)

- TOKAMAK fusion reactors

Nuclear Installed Base

Products, Spare Parts and services to maintain, modernize and extend the service life of facilities in operation; commission new facilities and support to decommissioning & dismantling activities.

Defense

Design and manufacturing of Safety Related Valves for nuclear powered submarines and aircraft carriers.

Cryogenics

Design and manufacturing of Cryogenic Valves for Liquefied Gases (LNG & LH2), Space facilities, particle accelerators, big science and nuclear fusion reactors.

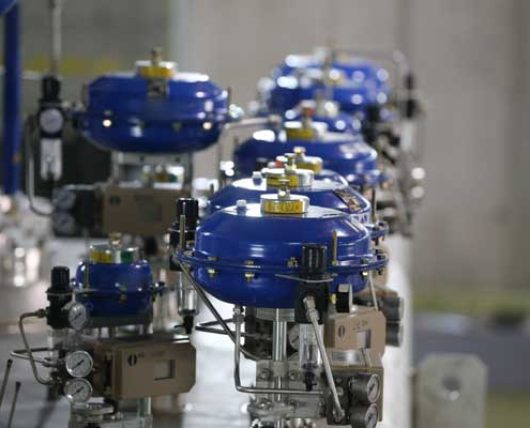

From left to right Nuclear class I High Pressure forged gate valves / Cryogenic liquid helium control valves installed in cold boxes ©Valserve

Engineering Excellence

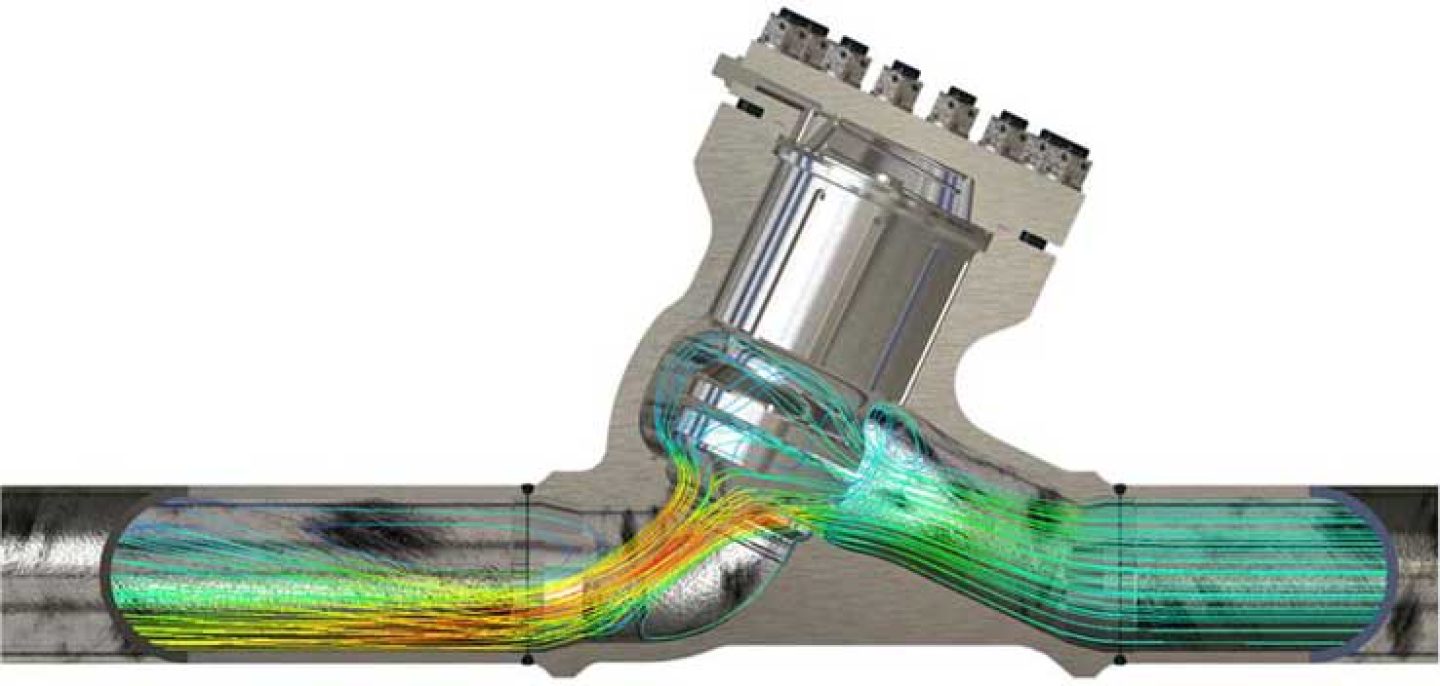

A dedicated team of 60 engineers and experts uses advanced tools (FEA, CFD, 3D modeling) to design valves that comply with the world’s most demanding nuclear design codes, including ASME III (USA), RCC-M (France), and NP-068 (Russia).

Flow simulation of a main feed water dampted check valve ©Valserve

Cutting-Edge Manufacturing

With 100 highly qualified staff and state-of-the-art equipment’s including computer numerical control (CNC) machining centers, plasma hard-facing machines, 3D metrology systems, and clean assembly rooms, we ensure consistent quality from design to delivery.

Large size valve body ready for machining on large bore CNC machine ©Valserve, Jean Fotso, March 24, 2010

Total Quality & Certification

Valserve’s quality management system and products are certified to the most stringent international standards: ISO 9001, ISO 14001, ISO 45001, ISO 19443, ASME III (N & NPT stamps), as well as ESPN (France), HAF 604 (China), OIT (Russia), CEFRI, and AEO.

Our maintenance tools & services

Valserve is one of the few valve manufacturers to have a specific and dedicated maintenance department, able to perform training, valve maintenance and upgrading in inside nuclear reactors containments.

Our teams, composed of 50 highly qualified engineers and technicians in mechanical engineering, electricity, welding and machining, are able to serve our clients everywhere in the world,

Maintenance tools :

- METEOR : Modular Equipment for Tightness Evaluation and On-Site Requalification

- OMERUS : Tool for Measuring Hard Facing Deposit Coating Thickness

- STEPHAN : Calibration tool for Valserve pneumatic actuators

- VELSCAN : On site diagnostic system for air operated actuators

Maintenance training ©Valserve

Velan SAS to Valserve: 50 years of valve leadership

1974

Velan inc. (Canada) establishes in France in Joint Venture with ALSTHOM (France) and supplied Nuclear valves to all 58 French Nuclear Power plants (PWR technology) since that date.

1989

GEC-ALSTHOM VELAN acquires the nuclear valve activities of SCHLUMBERGER (Previously SEREG valves) and transferred all its activities in Lyon (France).

1999

GEC-ALSTHOM VELAN becomes Velan SAS, a 100% subsidiary of Velan Inc.

2000

Velan SAS acquires the valve activities of BOUVIER-DARLING and ADAREG.

2005

Velan SAS selected to be the main supplier for the EPR technology and supplied all critical valves for Olkiluoto 3 (Finland), Flamanville 3 (France), Taishan 1 & 2 (China), Hinkley Point C (UK), Sizewell C (UK) reactors since that date.

2008

Velan SAS is selected by major Chinese engineering companies to supply nuclear classified valves for CPR1000 and ACP1000 nuclear reactors fleet and successfully passed the HAF604 certification.

2015

Velan SAS receives ASME III certification for Construction of Nuclear Class I, II and III valves in Lyon manufacturing plant.

2018

Velan SAS selected by ITER Organization to supply critical nuclear and cryogenic valves for ITER fusion reactor.

2020

Velan SAS Nuclear control and gate valves are selected for new VVER 1200 reactors in China (TW and XDP)