Design and fuel manufacturing

Assemblies skeleton visual control in the assemblies workshop © Framatome, Cyrille Dupont (The Pulses)

Framatome develops safe and high-performance fuels for all types of reactors.

Framatome has Research and Development units, fuel manufacturing facilities, and a fully integrated supply chain. Our sites are located in France (in supply chain order: Jarrie, Ugine, Montreuil-Juigné, Rugles, Paimboeuf, Romans and Lyon), in Germany (Karlstein, Lingen and Erlangen) and in the United States (Richland and Lynchburg).

Additionally, Framatome develops and manufactures specific fuels for research reactors (CERCA), covering a wide range of technologies.

260,000 fuel assemblies manufactured by Framatome power more than 200 reactors in operation worldwide.

Fuel: A blend of materials, components and expertise

Framatome’s scope of intervention is based on five areas of expertise:

- Development & design of fuel assemblies: Expertise in product design and neutron, thermo-hydraulic, thermo-mechanical and mechanical calculation codes and methods, extended databases.

- Production of zirconium and its alloys: Chemistry and metallurgy technologies, technology transfer.

- Fabrication and commercialization of fuel assemblies: Chemistry of reactions and solids, powder metallurgy, assembly, welding operations, NDE, nuclear safety and radiation protection analyses, programming, technology transfer.

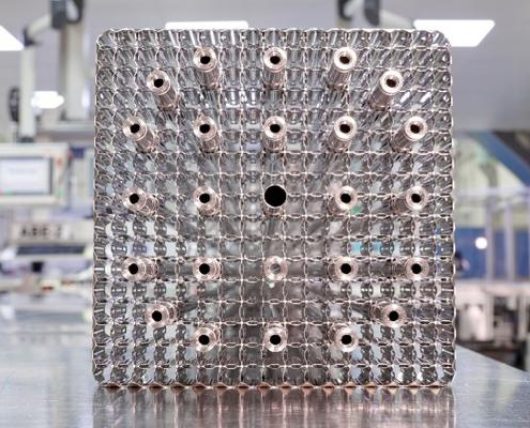

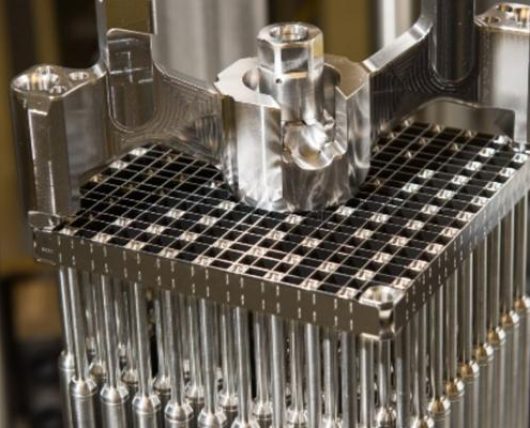

- Fabrication of fuel elements for research reactors: Use of metallic uranium, CERCA Research and Innovation Lab (CRIL) and prototyping center.

- Associated fuel services: Engineering, fabrication, on-site interventions on nuclear power plant sites.

Did you know?

Zirconium is a key material in the production of nuclear fuel. This metal is particularly resistant to corrosion by water and seawater. Combined with ideal nuclear characteristics (transparency to neutrons), its use is widespread for cladding fuels used in all types of light water reactors

Cutting-edge technologies used at every stage in the process

Fuel design & engineering services

Our engineering teams design safe, reliable and performant fuel & rod cluster control assemblies, developing and maintaining cutting edge codes and methods to conceive and license core and fuel assembly designs. With over 100 certified experts, we provide high-level engineering services, covering core management, safety analysis, and research on advanced fuels and reactors. Located at four sites in France, Germany, and the United States, we serve one-third of the reactors in operation worldwide and collaborate with all major safety authorities to ensure the quality and performance of our solutions.

Manufacturing of zirconium components

We control the entire zirconium manufacturing chain, from sponge production to the transformation of alloys into finished products such as tubes, bars, and flat products. We use efficient processes, supported by our Research Center in Ugine. As a world leader in nuclear-grade zirconium, we hold a 30% market share for fuel cladding and Zr sponge, while also developing special alloys for medical prostheses under the Framatome Healthcare brand. With several sites in France, a joint venture in China, and international teams, we combine innovation and excellence.

Manufacturing of fuel assemblies

The manufacturing of fuel assemblies covers the entire process, from uranium conversion chemistry to the assembly of complex technical components. We produce assemblies for all types of light water reactors (PWR, BWR) as well as uranium dioxide (UO₂) powders and gadolinium rods. Our innovations include advanced accident-tolerant fuels (PROtect E-ATF), higher uranium enrichment, and high burn-up rates.

Video: PROtect

[A presentation video set to dynamic music, with no voiceover. It features a series of slides made up of photos and text.]

Framatome’s PROtect Enhanced Accident Tolerant Fuel Program

Taking nuclear fuel to the next level

Our experts, with contributions and support from agencies across the globe, have made Framatome’s PROtect program the industry leader in accident tolerant fuel.

As a response to the 2011 Fukushima accident, Framatome initiated the enhanced accident tolerant fuel (E-ATF) program to improve safety for nuclear plant operators.

For the past decade, we have aggressively pursued technologies and solutions for the industry and our customers. Our near- and long-term solutions and implementations are unmatched in the industry.

Our solutions have been implemented in reactors around the world.

- 6 implementations worldwide

- 6 different reactor types

- 2 in Europe

- 4 in the U.S.

- more than 120 million chromia-enhanced pellets manufactured

- 400+ chromium-coated full-length rods in operation

How did we get there?

> 2013-2015: General Materials Research

After extensive research and testing, Framatome selected chromium-coated cladding for our industry-proven fuel rod cladding and chromia-enhanced UO2 pellets as a near-term solution.

Less than 18 months later, we delivered these materials to a commercial nuclear reactor for insertion to validate expected performance.

> 2016: First Use in a Commercial Plant

Industry first: Chromium-coated lead fuel rods inserted into a European reactor.

> January 2019: First Delivery to U.S. Customer

First full-length chromium-coated lead fuel rods containing chromia-enhanced pellets inserted into a U.S. commercial reactor.

> End of 2019: Making Progress

First Commercial GAIA Fuel Reload Complete with Enhanced Accident Tolerant Fuel Pellets.

> September 2020: GAIA Enhanced Accident Tolerant Fuel Assembly Completed First Cycle in U.S. Reactor

After 18 months, inspection results showed excellent performance and operating as anticipated.

> February 2021: First Delivery for BWR Application

Enhanced accident tolerant fuel rods inserted into a boiling water reactor (BWR<a/bbr>) – first Framatome application in this type of reactor.

> March 2021: Complete PROtect Fuel Assembly Put into Operation

176 chromium-coated fuel rods and more than 40,000 chromia-enhanced pellets comprised this first complete enhanced accident tolerant fuel assembly in the world.

> June 2021: Technologies Complete Life Cycle

PROtect cladding completed first life cycle at Gösgen. Cladding was discharged after 5 cycles of operation, demonstrating excellent performance and visual results.

> March 2023: Preparing for Commercial Deployment

First-ever complete PROtect fuel assembly finishes 1st cycle of operation safely, withstanding in-reactor conditions to perform as designed.

> September 2023: Moving Toward Industrialization

Launched procurement of industrial pilot line to produce more than 100,000 chromia-coated rods per year.

> July 2023: EDF First

Lead test rods inserted into an EDF reactor; further collaboration with EDF for additional testing.

> December 2023: Operation Complete

PROtect GAIA fuel assembly finishes 56-month lifecycle of operation in U.S. reactor, demonstrating expected results.

> May 2024: Higher Burnup Limits Achieved

First E-ATF technology to operate full-length fuel rods at increased operational limits.

> June 2024:

Groundbreaking on new facility dedicated to mass production of chrome-coated rods.

> 2025 and Beyond: Future Development

Complete first irradiations of silicon carbide (SiC) fuel cladding concept.

> 2026: Complete licensing of PROtect chromium-coated cladding.

> 2027: Irradiation of SiC cladding in a commercial nuclear power plant. Batch reload readiness for PROtect chromium-coated cladding and chromia-enhanced pellets fuel concept.

Taking nuclear fuel to the next level

A complete range of safe and competitive fuel products

Framatome’s fuel product portfolio covers all types of light water reactors. They are available for refueling and worldwide. Among them are GAIA fuels suitable for Pressurized Water Reactors (PWR) and ATRIUM 11 fuels for Boiling Water Reactors (BWR).

Framatome is playing an increasingly important role in supplying fuel for VVER reactors operated in Europe. The company is developing a sovereign and 100% European fuel for VVER-1000 and VVER-440 reactors.

Manufacturing of fuel elements for research reactors

Framatome manufactures fuel elements to supply research centers and universities operating research reactors for industrial and scientific purposes. The company also produces uranium-based irradiation targets for medical use, used to generate radioisotopes such as iodine-131, xenon-133, yttrium-90, and molybdenum-99, the latter being the most used for nuclear medical imaging exams, particularly for cancer diagnosis. This activity is now part of the Framatome Healthcare brand.

With over 20,000 fuel elements and 80,000 medical irradiation targets manufactured, Framatome offers 70 different designs of fuel elements. Each year, approximately 30 million nuclear medicine exams worldwide use targets produced by CERCA.

Launched in 2019, the CERCA Research and Innovation Laboratory (CRIL) is dedicated to the development of uranium-based fuels that contribute to international research in physics and medicine.

Video: CRIL

[Presentation video of the CRIL, located in Romans-sur-Isère, France — the research and innovation laboratory of Framatome’s CERCA division. The video is narrated by a female voice-over and features commentary from Bertrand Stepnik, Head of CRIL. The narration is illustrated with video sequences of the laboratory and its operators at their workstations.]

– Voice-over: At Framatome, innovation is our driving force. Welcome to the CERCA Research and Innovation Laboratory, a space dedicated to uranium based fuel development, prototyping and manufacturing of advanced nuclear fuels for all types of reactors.

– Bertrand Stepnik (Head of CRIL): Here at CRIL, we continuously innovate to develop the nuclear fuels tailored for the reactors of tomorrow.

– Voice-over: With over 65 years of experience in fuel fabrication and thanks to the know-how of our CERCA division, we accelerate the development of your fuel elements and convert your concept into reality.

– Bertrand Stepnik: Our team, composed of experienced researchers and emerging talents, collaborates closely with academic and industrial partners worldwide to develop customized projects.

– Voice-over: Located in France, just south of Lyon, our modern facility is equipped with state-of-the-art technology to rapidly develop and fabricate a wide range of nuclear fuel prototypes.

– Bertrand Stepnik: In 2022, we achieved a world first by winning the SFEN Innovation awards for our 3D printing uranium-molybdenum objects.

– Voice-over: We develop new and innovative technologies, such as metallic uranium and uranium oxides for any type of reactor including next generation, in collaboration with international partners.

– Bertrand Stepnik: Our flexibility allows us to produce single prototypes as well as small series while maintaining high quality standards.

– Voice-over: At CERCA Research and Innovation Lab, we are more than just a laboratory. We are your partner in turning your ideas into reality, for today and for tomorrow.

– Bertrand Stepnik: Your challenge, our solution. Together, we develop the fuel for the future.

A preferred partner for advanced reactors

Framatome leverages its expertise and proven technologies to support the development and commercialization of fuel for advanced reactors and Small Modular Reactors (SMR). By using available and qualified solutions, Framatome reduces development time and optimizes fuel cycle costs by integrating ready-to-use components.

To support the future of nuclear energy with reliable and high-performance fuel solutions, Framatome has established the Innovative Reactor Fuels Hub, dedicated to the development and supply of fuel for new types of nuclear reactors. This Hub brings together our technical expertise, industrial capabilities, and advanced technologies to support every stage of fuel development. It helps our customers design, test, and deliver the right fuel for their innovative reactor projects, quickly and efficiently.

Service and expertise

Framatome develops its cutting-edge codes and methods, such as Arcadia and Galileo, for the design and justification of fuel assemblies and reactor cores. Realistic 3D modeling tools ensure precision, robustness, and compliance with regulatory requirements. They optimize reactor operation, improving flexibility and safety margins. Based on a global validation database, Framatome’s solutions facilitate licensing and ensure safe and efficient operation of nuclear facilities.

The use of Artificial Intelligence helps maximize the efficiency of certain engineering studies by optimizing solutions for our clients and in our development projects, without replacing the regulatory licensing methods.